Here is a detailed article about the University of Tokyo’s breakthrough in ScAlN thin film fabrication, written in a polite and informative tone:

University of Tokyo Achieves Breakthrough in High-Quality ScAlN Thin Film Fabrication Using Sputtering Method

Tokyo, Japan – August 8, 2025 – Researchers at the prestigious University of Tokyo have announced a significant advancement in materials science with the successful fabrication of high-quality Scandium Aluminum Nitride (ScAlN) thin films utilizing a sputtering deposition technique. This achievement, detailed in a recent press release, holds considerable promise for the development of next-generation electronic and optoelectronic devices.

ScAlN is a ternary nitride semiconductor material that has garnered substantial attention due to its unique piezoelectric properties, particularly its high electromechanical coupling coefficient when alloyed with scandium. These properties make it an attractive candidate for a wide array of applications, including high-frequency acoustic devices like surface acoustic wave (SAW) and bulk acoustic wave (BAW) filters, piezoelectric transducers, and potentially even advanced sensors and actuators.

However, achieving high-quality ScAlN films with precise control over composition and crystal structure has historically presented significant challenges. Traditional methods have often struggled with issues such as poor crystalline quality, compositional inhomogeneity, and the presence of undesirable defects, which can limit device performance and reliability.

The University of Tokyo team, through their meticulous research, has demonstrated a novel approach using sputtering deposition that overcomes these limitations. Sputtering is a physical vapor deposition (PVD) technique that involves bombarding a target material with energetic ions, causing atoms to be ejected from the target surface and then deposit onto a substrate. By carefully optimizing the sputtering parameters, including the gas mixture, pressure, substrate temperature, and power applied to the target, the researchers have been able to grow ScAlN thin films with exceptionally high crystalline quality and excellent control over the scandium content.

The reported success in producing high-quality films is crucial because the piezoelectric properties of ScAlN are highly sensitive to the scandium concentration and the film’s crystal orientation. The ability to reliably control these aspects through the sputtering process opens doors for tailoring the material’s properties for specific device requirements. This level of precision is vital for unlocking the full potential of ScAlN in demanding applications where performance and efficiency are paramount.

This advancement is expected to accelerate the commercialization of various technologies that rely on high-performance piezoelectric materials. For instance, the demand for smaller, more power-efficient, and higher-frequency communication filters in mobile devices and wireless communication systems continues to grow. ScAlN’s superior properties compared to traditional piezoelectric materials like lithium niobate (LiNbO3) or aluminum nitride (AlN) position it as a strong contender to meet these evolving needs.

The University of Tokyo’s contribution underscores their commitment to pushing the boundaries of scientific understanding and technological innovation. This successful fabrication of high-quality ScAlN thin films via sputtering represents a critical step forward, paving the way for the development of more advanced and performant electronic components that will shape the future of technology. Further research and development are anticipated to build upon this significant achievement, leading to practical implementations in a variety of cutting-edge applications.

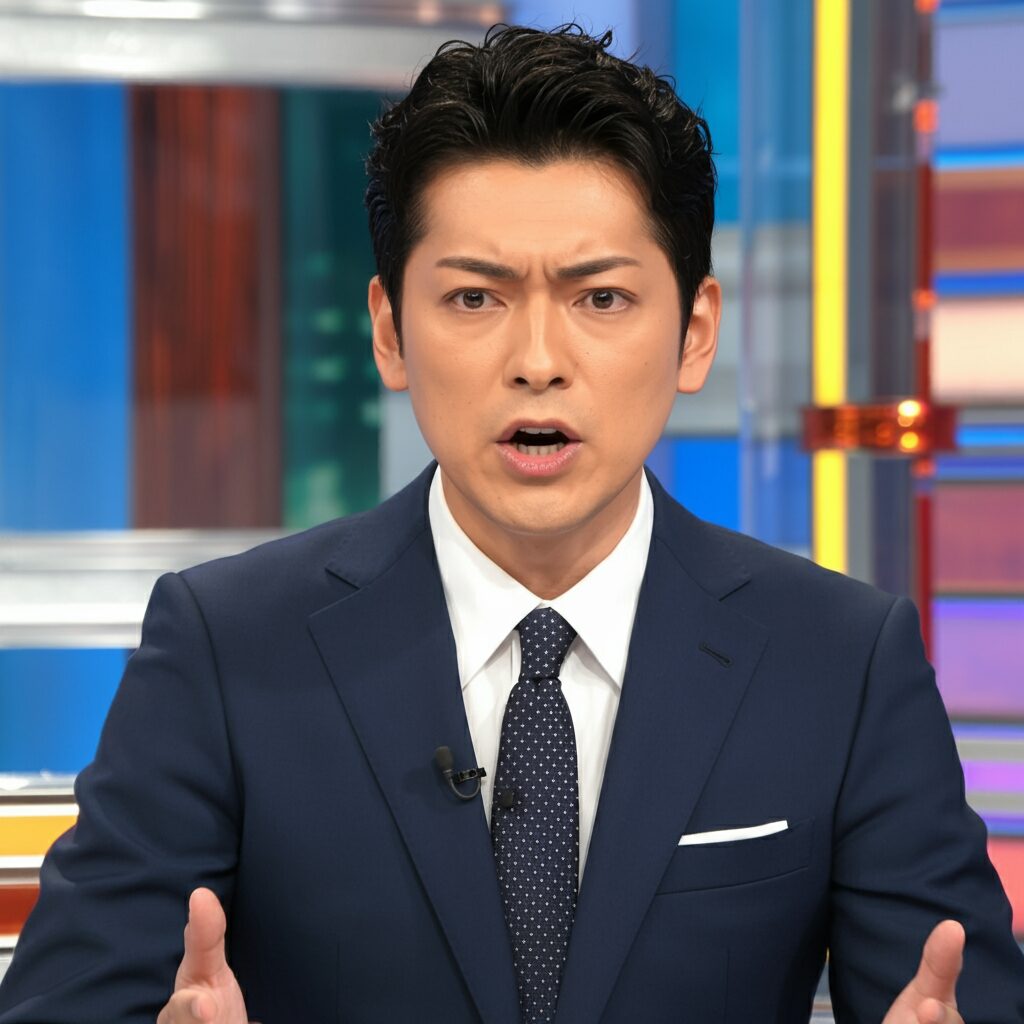

AI has delivered the news.

The answer to the following question is obtained from Google Gemini.

東京大学 published ‘スパッタ法を用いて高品質なScAlN薄膜の作製に成功’ at 2025-08-08 04:00. Please write a detailed article about this news in a polite tone with relevant information. Please reply in English with the article only.